Gelatin vs. Gelatin Hydrolysate - What is the difference anyway?

Depending on the type of product, gelatin or gelatin hydrolysate can be used to perform particular functions toward a number of tailored specifications including taste, texture, thickness, gel strength, and many more.

Gelatin is defined by its bloom, or gel strength. It forms a thermoreversible gel at room temperature, and requires hot water to dissolve. Therefore, it performs such tasks as gel former and texturizer in fruit gums and gelatin desserts, a stabilizer in dairy products such as yogurts or puddings, and an emulsifier in soups, sauces, and low fat food. If a particular product needs its ingredients brought together to form the optimal consistency or strength, gelatin is the perfect adhesive for the job.

Gelatin has a neutral taste and no odor, so it can be used in food applications without altering taste. Further, it can act as a whipping agent and foam former in marshmallows, ice cream, cake fillings, and mousse desserts. It is also a great source of protein.

Gelatin hydrolysate, on the other hand, is defined by its viscosity, or thickness. It forms a solution at room temperature, and most types dissolve at room temperature in cold water.

Gelatin hydrolysate is also an ideal source for protein. It is made only of highly purified protein, and contains all but one (tryptophan) of the essential amino acids the body requires from outside sources for protein. However, since gelatin is only one of many proteins in our daily diets, it is still easy to get more than enough needed protein from our daily food intake. It can be used as a thickening and binding agent, so it is able to partially or completely replace sugar as an adhesive in some products, further improving their health capabilities. Gelatin hydrolysate is also neutral in taste, so it provides no adverse flavor to foods. It is used to improve a wide array of products, including protein bars, cereal bars, protein drinks, smoothies, and joint health and nutraceuticial products.

Although GELIKO kosher gelatin and kosher gelatin hydrolysates can be used for different applications, the benefits they provide are endless. Whether you are looking to improve the physical characteristics of your products, such as texture or weight, you want to improve their functional characteristics, such as gel power or thickness, or you want to increase their nutritional value. GELIKO kosher gelatin and kosher gelatin hydrolysate are the ideal ingredients to accomplish any or more of these goals.

Kosher Gelatin: Functional & Nutraceutical Properties

Gelatin is a hydrocolloid; a protein or polysaccharide that, when mixed with water, provides textural effects such as thickening and gelling. Gelatin's unique amino acid composition and structure provide a range functional properties. Remarkable functionality combined with bland taste, color, and aroma make Geliko kosher gelatin an ideal choice for texturizing an array of kosher food, cosmetic, and pharmaceutical applications.

Gel Formation

Geliko kosher gelatin forms gels that are thermoreversible. Hot solutions as low as 0.5% gelatin will solidify when cooled, and revert back to a viscous solution if heated again. This transition can be performed repeatedly.

The relative gel strength of a gelatin product is indicated by its "Bloom" value, a measure of resistance to compression of a 6.67% gel prepared and held under prescribed conditions. Higher Bloom gelatins form stronger gels than lower Bloom gelatins (at the same concentration).

Gel strength is also affected by concentration, conditions of preparation such as temperature, pH, solids, etc., and the presence of other hydrocolloids such as agar, pectin, or carrageenan.

The following graph illustrates how gel strength varies with Bloom number.

In addition to increased gelling capacity, gelatins with higher Bloom strength will exhibit the following characteristics:

·Solidification temperature is an important consideration when incorporating kosher gelatin into systems that require rapid gel formation (quick-set gummy candies, for example)

·Melting temperature will affect the mouthfeel of the finished product, allowing developers to create textures ranging from strong and chewy, soft and creamy

·Reduced usage level (to obtain the same gel strength as with a lower Bloom gelatin)

·Lighter color/increased transparency

·More neutral taste and aroma

·Thickening

Aeration

Geliko kosher gelatin and kosher gelatin hydrolysates can be used to create foams. By decreasing surface tension, gelatin stabilizes aerated systems. (Surface tension effects also serve to stabilize emulsions such as those used for vitamin embedding.)

Film formation gelatin is able to stabilize surface interfaces by forming a film. This is an important function if disperse phases are to be protected within a particular medium. These effects are fully utilized in the production and stabilization of foams and emulsions. The surface tension of aqueous systems can be reduced by using gelatin.

Effect of pH on gelatin

The manufacturing process of gelatin determines its isoelectrical point (IEP), the pH at which the charge on the gelatin molecule is zero. The IEP of acid (Type B) processed gelatin such as Geliko kosher gelatin is between pH= 8.0 to 9.0.

At the isoelectric point, gelatin swelling, viscosity, and gelation are minimized, while gel strength, syneresis, turbidity, and foaming are maximized. Finished product pH is, therefore, a crucial factor to consider when selecting a gelatin product.

Nutraceutical properties of gelatin

Geliko kosher gelatin hydrolysates are a rich source of health-enhancing amino acids that enhance virtually any nutritional food, beverage, health and beauty aid, or pharmaceutical application. Gelatin hydrolysate contains high levels of arginine, essential for muscle cell metabolism, and glutamine, shown to reduce the effects of metabolic stress.

In a comprehensive range of clinical studies, it has been shown that gelatin hydrolysate can help maintain healthy joints, ligaments, and tendons.

Gelatin hydrolysate is also used in beauty products designed to enhance hair and nail growth, and promote healthy skin.

Geliko Raw Material

|

Only kosher cattle hides/skins are used in the manufacturing of Geliko kosher gelatin.

These raw materials are subject to the same stringent quality control guidelines utilized by the kosher meat processing industry. Hides are meticulously tracked to eliminate any non kosher hides from the gelatin manufacturing process.

Kosher gelatin products exhibit the same physical and functional characteristics as their non-kosher counterparts.

Geliko Production

Geliko kosher gelatin is derived from cattle hides obtained from cattle slaughtered following the strictest kosher guidelines for slaughter and tracking to ensure the elimination of non kosher hides from the gelatin manufacturing process.

|

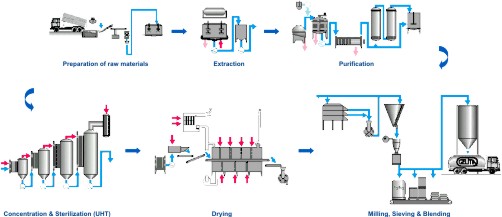

Production Process Flowchart - Diagram |

|

|

Geliko kosher gelatin manufacture follows the "Type A" or "acid" process. Washed hide undergo a treatment with acid to render the collagen soluble in warm water, a precondition for the subsequent extraction process. Following this step, excess acid and salts are washed out with water.

Gelatin is then extracted from the raw materials using a warm water continuous or a multi-stage extraction system. The material extracted in any one stage is subjected to re-extraction with water at a higher temperature. This process is repeated until all of the gelatin has been extracted.

Extracted gelatin is isolated using high-performance separators. Any mineral salts remaining are reduced or removed as required.

The purified, concentrated gelatin solution is sterilized, and then extruded through perforated disks to form "noodles". The gel gelatin noodles are then dried in a band drier supplied with filtered, dehumidified and disinfected air, coarsely ground and then placed in quarantine for quality control testing.

Only when gelatin, that meets all physical, chemical and biological testing specifications it is released for further use.

Geliko kosher gelatin is manufactured by global gelatin manufacturer Gelita. Raw materials provision, logistics and transport systems are monitored and maintained by Geliko as well as Gelita to ensure the safety, freshness and traceability of all raw materials. All Geliko kosher gelatin is manufactured in ISO 9000 certified facilities, following kosher process guidelines established by the Orthodox Union (OU).

|

|

|

||

|

|

|

||

| Cattle Hides | Acid Process | Isolation | ||

|

|

|

||

|

|

|

||

| Concentration | Drying | Milling and Screening |

Gelatin Overview

Kosher gelatin is obtained from collagen found in the hides of kosher slaughtered cattle.

Native collagen is a scleroprotein based on a polypeptide chain comprised of more than 1,000 amino acids. Three of these chains form a triple helix. Groups of triple helices produces fibrils of collagen stabilized by cross-linking, forming a 3-dimensional network structure that is insoluble. Collagen is converted to a soluble form by through enzymatic hydrolysis. Carefully controlled partial hydrolysis yields gelatin, while complete enzymatic hydrolysis as produces gelatin hydrolysate.

Chromatographic analysis indicates that gelatin products are made of peptides. Gelatin hydrolysate contains many small peptides and exhibit molecular weights between 500 and 15,000, with an average value of about 3,000.

Gelatin consists of much larger peptides with molecular weight up to several hundred thousand.

The amino acid content of collagen, and hence of gelatin and gelatin hydrolysate, is very specific, with about one third glycine and 22% proline and its hydroxylated form, hydroxyproline.Commercially available edible gelatin has the following composition:

- 85% to 90% protein

- 8% to 12% water

- 2% to 4% mineral salts

Gelatin is missing only two amino acids; cysteine and tryptophan. Because tryptophan is an essential amino acid, however, gelatin is considered an incomplete protein.

| Main Menu |

|---|